HFMI – other crack types

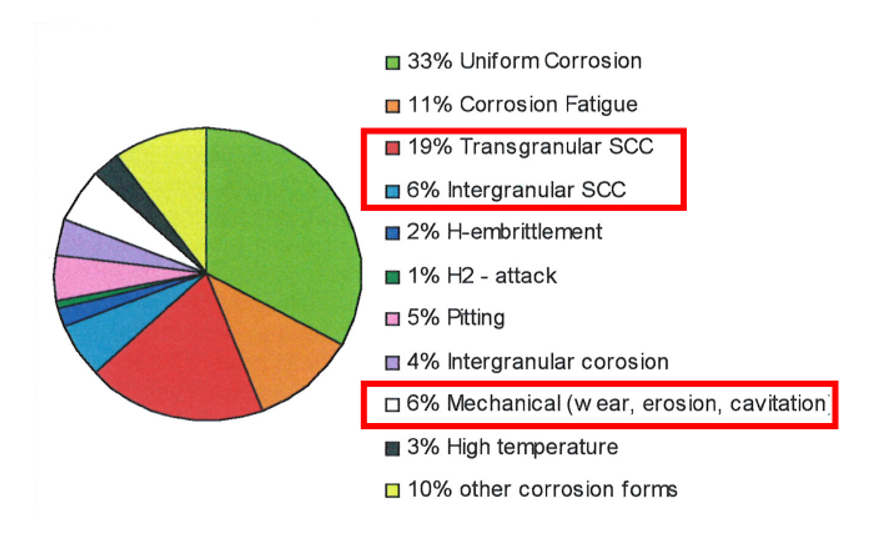

In the chemical industry, other cracks than fatigue cracks occur due to corrosion or high service temperature. In the circle diagram the frequency of failure modes in a German chemical plant is shown (Source: Corrosion Engineering Guide - G. Notten). In 3 cases, tensile stress is important:

- SCC – Stress Corrosion Cracking

- Thermal fatigue (cyclic heating and cooling)

- Stress relaxation cracking (crack which occurs when temperature increases fast during startup of a chemical reactor)

The introduction of compressive on the most critical spots with HFMI, can delay or even prevent the occurrence of these cracks.

Baaten Welding Consultancy offers:

- Damage analysis which provides insight in the use of HFMI in chemical reactors.

- Application of HFMI.

Frequency of failure modes in a German chemical plant (Source: Corrosion Engineering Guide - G. Notten)